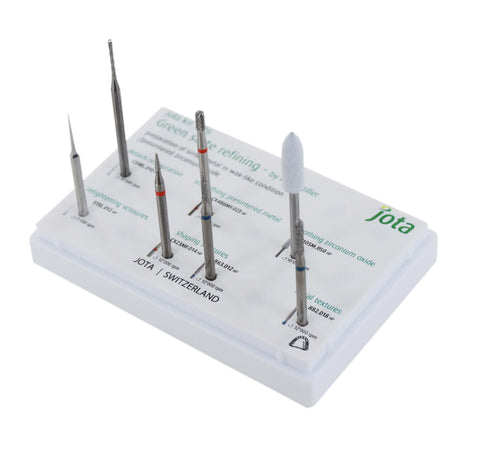

Sintered Metals, Unsintered State (1926) Laboratory Kit

Characterize of sintered metals in the green state and final polishing of the sintered restoration.

- Safe removal of the restoration from the blank with a specially developed cutter.

- Unique fissure shaping by means of a new special tool.

- Optimally designed polishing sequence for a perfect shine.

“Soft metal” as Ceramill Sintron® is revolutionising the production process for dental restorations based on non-noble metals. The blanks are made of a pressed alloy of chromium, cobalt and molybdenum, which is kept in shape by means of binder. Dental restorations are milled in the preform state. Because of the “waxy” consistency of the sintered metal this can be worked effortlessly and quickly in-house with a desktop milling unit. Here CNC dry working of the sintered metal has clear advantages over a traditional, labour-intensive casting process or external milling from a CoCr blank. After the sintering process the material acquires a very homogeneous, dense and bend-resistant microstructure with a final density of > 98% and a manufacturer-dependent shrinkage rate of 7 - 8.5%. The low shrinkage factor guarantees high torsional stability during the sintering process. The subsequent facing of the material can be carried out with any conventional non-noble-metal framework ceramic.

Made in Switzerland.

For more information on this kit and the procedure Click Here

We Also Recommend