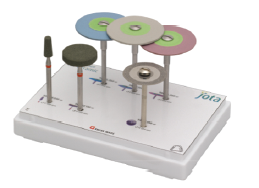

Finalizing Sintered Metal Restorations (1927) Laboratory Kit

Characterize of sintered metals in the green state and final polishing of the sintered restoration.

- Safe removal of the restoration from the blank with a specially developed cutter.

- Unique fissure shaping by means of a new special tool.

- Optimally designed polishing sequence for a perfect shine.

“Soft metal” as Ceramill Sintron® is revolutionizing the production process for dental restorations based on non-noble metals. The blanks are made of a pressed alloy of chromium, cobalt, and molybdenum, which is kept in shape by means of a binder. Dental restorations are milled in the preformed state. Because of the “waxy” consistency of the sintered metal, this can be worked effortlessly and quickly in-house with a desktop milling unit. Here CNC dry working of the sintered metal has clear advantages over a traditional, labor-intensive casting process or external milling from a CoCr blank. After the sintering process, the material acquires a very homogeneous, dense, and bend-resistant microstructure with a final density of > 98% and a manufacturer-dependent shrinkage rate of 7 - 8.5%. The low shrinkage factor guarantees high torsional stability during the sintering process. The subsequent facing of the material can be carried out with any conventional non-noble-metal framework ceramic.

Made in Switzerland.

For more information on this kit and the procedure Click Here

Nous vous recommandons également